| Home | |

| Adventures | |

| Specification | |

| Diary | |

| Photo Album | |

| Contact Us | |

| Feedback | |

| Hints & Tips | |

| Polish Words | |

| Web links | |

| Problem | |

| Polish Yachts | |

Sticking down the last layer of Deck plywood & making up quadrants

12/04/08

9:30am start/ Off loaded two hardboard and two 6mm marine plywood sheets, and setup the tools. Cracked on with the deck templates of hardboard and made up the next two pieces of deck ply port, and the corresponding ones on starboard. Need to assess once all ply down, where weights might be needed whilst the plywood is epoxied in place. Weather perfect today. Just managed to stop for lunch and then knocked of at 16:00pm. Need to straighten my back after seemingly working doubled over for 6 hours. All going well so far.

|

|

|

13/04/08

Last night dug out the very long lengths of mahogany we’d had had to store down the side of the house, where least rain fell. They are approx 16’ in length – too long for the workshop. This morning loaded the roofrack and took this timber down to the boat and to stack in the new workshop straddled across the two workbenches lower shelves for now. Setup the tools to crack on with the deck ply pieces and then realised I’d no power. Doh. What’s gone wrong, have I blown the fuse, as it was all working when I left last night. No-one else around this morning to ask, to set to hand sanding the outer edge of the covering board portside – where most sun light was, and started investigating the covering board joint to the hull aft, which needs a good rake out and refilling. By 13:00pm (after I arrived at 9:30am) the site owner returned. The power had been turned off last night because someone else had gone home last night and left all lights burning. The owner had then got sidetracked this morning , and completely forgot to turn it back on before he left this morning. Phew, a relief all that was needed was to flick the switch back on. Now I know where it is in case it happens again. I had been about to pack up and go home, somewhat a little down having no power, and concerned I had blown something. Power back on and away I went. Next two deck ply pieces cut and screwed into place and pattern prepared for next pieces, which go around the cockpit side corner joints. Have had a good day today in the end, left about 17:00pm.

|

|

|

19/04/08

Good early start today just after 9:00am. Weather abmismal with heavy rain, but I could work on undeterred. Finished the patterns for, and cut out of plywood the next port and starboard ply deck pieces, and fixed in place with screws. So good so far, now to tackle the aft deck, then complete the remaining side pieces. The aft deck piece took some thought as the tiller bracket was now in place, locked in with a sheer pin, not to be disturbed. I was still contemplating how to make up the cabin sides to deckply edging strips. Builders merchants have nothing in mahogany quadrants suitable at all. Proceeded to wrestle with the hardboard pattern making for the aft deck pattern. I was hoping could have made it all in one piece, but in the end needed to cut the plywood down the center (around the tiller bracket), in to two pieces. The hardboard pattern was made in one piece. By 16:30pm the natural light levels were low even though I had three flourescant daylight bulbs on. It got to point where I could not see my pencil markings on the hardboard, old age catching up, I’m sure. Had a good day, with usual stock of sandwiches and flask of coffee – so called it a day late afternoon.

20/04/08

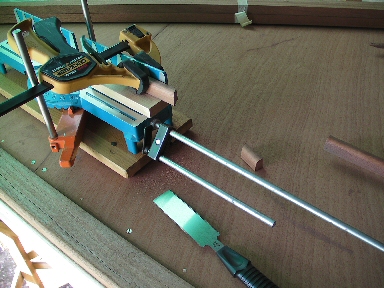

9:30am start. Intention was to see if I could make up some deck/cabin edging quadrant out of the best of the three 16’ mahogany lengths. Also while I had sheet of marine plywood on tressles, it made ideal work area to do this, using an old pine chair as the helping hands, to hold up the end of the lengths. Routered both edges of the best piece, with a rounded over edge. This piece will be cut down the middle later. I took it steady with the router having already set it up last night with the cutter I needed. Then further orbital sanded the top and bottom edges. I ought to have completed all the sanding before doing the routering, with hindsight, but never mind I’m learning fast. The mahogany was coming up well. Next was to cut this piece in half to leave me with two pieces of 21mm x 16mm quadrants. Without the bench saw here, and the timber too long to do at home, set to using the jigsaw with its fence. I had not gone far and had to abandon that idea – the fence was not suitable for cutting 16mm thick mahogany. It is quite tough fibres. Pencilled a line on the underside marking the halfway i.e. 22.5 mm, then with the jigsaw cut down this line. With hindsight should have marked it after sanding it and before routering it, and on the facing edge. I know next time. Anyway I now had two lengths of quandrant, which now needed chamfering on the back edge to fit the angle between the cabin side and deck plywood. Needs the scribing block which I don’t have with me. Job for next week so put the quadrants on deck, and swept up all the saw dust. Then reverted back to completing the after deck hardboard pattern for the deck ply. Took some improvisation and initiative but I did it all in one piece (except for the hole where the tiller bracket was). Will now need to drill out the holes in the corner of the aft covering board area so they are ready to fill with epoxy, and to hopefully plug them on the outside. Oh I nearly forgot whilst I had the router with me, I routered the tops of the Steps posts, which were quite sharp on the hands. Long overdue job. 16:00pm knocked off.

|

|

|

26/04/08

Weather wise this was the best day so far this year – but rain forcast tomorrow, when I’m going to the Beaulieu Boat Jumble. 9:00am start today. Decided the deck/cabin edgings I’d routered up last week, I would cut into two shorter lengths. 16’ length as it was was ideal, but with half the tools (machines) still at home and working single handed, it is much more manageable in shorter lengths. Will scarf in the joints. Main goal today was to complete the aft deck ply. The hardboard pattern was completed last week. Decided best to make seperate hardboard pattern of the tiller bracket tubing through the deck, and to cut the final deck ply in two pieces i.e. down the middle forward to aft. This was my biggest ‘pattern’ challenge yet, as all the edges had to be scribed in, so in all this piece of plywood took nearly three hours from cutting it by time it was screwed in place. It did look a good job done though, even though it will get covered up with flexiteek. I’m very pleased with it. Just a ply piece port and same starboard to complete, and hopefully get each out of one piece of ply about 5’ in length. Started making up the pattern for portside. Then checked out some measurements I am needing in preperation for the Boat Jumble tomorrow. Knocked off at 16:30pm. Had had a good day and in need of a rest.

|

|

27/04/08

Beaulieu Boat Jumble. It was worth the visit. Picked up call cards for two stainless steel workshops, and their goods on display did look good. I’d prefer to get all the fittings from the same place so they match etc. There was also a timber place which had a stall which was a pleasant surprise, so picked up a catalogue. The products look as good as I imagined. If I’d been fitting out inside, there was lots I would have bought – everything was superb.

04/05/08

Loaded all the tools back into the van ready for the boat. Then hoovered the lounge which I could see once again. Got to the boat and setup shop by 8:30am. Then realised I had forgotten to pickup my tape measure. Doh. Anyway for what I was doing I did not need a tape measure. Proceeded and managed to complete the patterns for, and cut out of plywood, for the last afterdeck side sections port and starboard. By now it was midday – so had lunch etc. Could not screw these pieces of ply in place because I’d not got my tape measure with me. There had to be something I needed a tape measure for. I was quite tired now (had been a busy week with early morning work shifts and late nights at work). Tired I must have been because all along - I realised later – that I’d had had my tape measure in my top jacket pocket. It then poured down with rain – so not wanting to get stuck at the field entrance, I packed up and got out quick.

05/05/08

9:30am start today. 1st job was to drill and screw in the place the last two pieces of deck ply sections made yesterday. Lots of rain last night, so played safe today and parked the van in the main yard. All done screwing down these ply pieces, then I unscrewed them all one by one, counter sinking in the screws and sanding down the screw hole areas, checking as I went along the height of the plywood against the covering board to get it as even as possible. Will need some grip fast nails in addition to the screws, on the two forward most ply pieces, where there is considerable bend in the plywood. The nails will go in between the screws, when it is finally glued into place. So far I am pleased with progress and satisfied with the outcome.

10/05/08

Mentally tired this week due to work commitments, and then my broadband connection died on me, hopefully temporarily. Down at the boat by 9:30am. Setup and completed the remaining starboard deckply pieces i.e. removing them, coutersinking the screws and sanding the screw holes etc, ensuring not too tight a fit then screwing back down. Then made up a pattern for a thin missing deck ply piece on the forward cabin coachroof, just forward of the brass hatch. Need to get this in place, so the cabin edgings can be done. Confirmed the quadrant edging I had done so far (the test piece) for the cabin sides to the deck is perfect, so will carry on and finish

|

|

these quadrants at home on the band saw, in the lounge, with the dust extractor of course.

Had a good study of the cockpit corner ‘coming’ areas where cockpit sides meet the corner joints, and how to do the edgings of the coach roofs to be finished items and to accommodate the flexiteek. More brain ache stuff. Made a pattern of the angle of the main cabin frontage to the forward coach roof deck. 3:30pm too tired – so packed up and called it a day. Then I got distracted whilst packing up and after a quick chat with the site owner, inspiration took over, and ended up sanding the temporary drop boards – to take home – and give a coat of woodsealer. It will tidy them up a bit, as they are very weathered, and will be more appealing until the real dropboards are made in the future. I investigated how bad the port cockpit side upper edge was, nearest the joint to the main cabin. It could be possible to scarf in a piece of mahogany. It is not as bad as first thought once I cleared away the loose fibres. The starboard side is ok, and it would be toooo much a mammoth task to try and take down these corner jointings. Needs further consideration. It was 17:00pm when I finally left, with a long list of ‘todo’ this week.

11/05/08

During the week I had cut the angle on the cabin/deck edging quadrants, with the bandsaw and the help of record rollers for support.

17/05/08

Another mentally tiring week at work, and still trying to get my broadband back. Down at the boat by 9:45am. The field was dry so got the van right up to the boat. Set to cutting out of plywood the pattern for the missing ply piece forward of the brass hatch. I had sourced a suitable piece of plywood from the stock in the workshop. Long overdue job, finally done just needs epoxing in place.

|

|

|

|

|

|

Started sanding down cabin/deck quadrants further to remove the marks the router cutter leaves in places. Mahogany is tough fibres and is known for cross grains. Then decided to take the tabernacle off to take home and arrange for electro-polishing, and get quote for fairleads and cleats at same time. Then was the task of removing the neoprene rubber piece which had been under the tabernacle to help seal the holes, and it had done a good job. Then sanded the mast-step piece plus around the forward brass hatch, then gave both a couple of coats of woodsealer. On the mast-step the original top gloss we’d painted on had weathered through in place, and we’d not been able to touch up at the time. Also today sanded down the cockpit well temporary hatch, then gave it a couple of coats of woodsealer. Just tidies it up a bit. 17:00pm finished for the day.

18/05/08

Started last night, and continued this morning, to sort through all the mahogany lengths in the shed, to find suitable pieces for corner edgings on Emerald. I found what I was looking for, plus the sift through was timed right. Down at the boat by 10:00am. Did further sanding on the cabin/deck edging quadrants. Then sanded down the mast-step, and removed the main hatch so I could sand down the runners and frame on the outside. Then I went around the mast-step, forward hatch frame, Main hatch runners and frame with a coat of woodsealer. These previously had woodsealer on them, so best to stick with same product, and touch up and restore. It starts to add some final finish looking parts to the boat. Gave the main hatch area another coat of woodsealer, before putting main hatch back. Most of the afternoon was spent routering a rounded edge on a 4’ length to be the quadrant of forward cabin to deck. This piece just needing some sanding first before routering, and to workout the best edges in question. My workbenches are just the job, with gap between they are ideal. The mahogany is tough in places, and had to resand afterwards the odd burn marks the router had left behind. Where the wood was softer there was no burn marks – but there was very little softer wood!!. All was looking good by the time I had finished at 16:00pm today.

|

|

24/05/08

By 10:00am down at the boat, with visions on commencing epoxying in place the plywood on deck. Nervous at doing this because it is the first time on my own single handed – well two actually one pair of hands !. I offloaded the necessary tools etc and setup stall, and prepared and epoxied down the foremost piece of ply at the fore peak. Nailed in some small gripfast, but blow me the wood pad & fixings beneath the lower deck ply was rock hard, and at the last mm the nails stopped. Just managed with punch to knock them in all the way. Nails needed between the screws to pull the plywood down as level as possible to the covering board edge. It was blowing a gale outside, and causing a draft though the out buildings.

|

|

|

|

|

The next forward ply piece is approx 5’ x 4’ I’m going to need additional pair of hands, and too windy today to contemplate starting this one. With the leftover epoxy from the forward ply piece, epoxied in place the narrow ply strip in front of the forward hatch. Then the remaining epoxy left over, I poured into the cleaned out gap on the starboard cockpit corner jointing. 13:30pm now. Having found the main coachroof coming pattern for potentially fitting a canopy etc, I scribed it in better today as I will need to consider if providing for a possible canopy over the main hatch/cockpit area or not, before I get the flexiteek down. 16:00pm now and not really having stopped since 10:00am this morning, called it a day.

26/05/08 Bank Holiday.

Weather was bad and forecast another attrocious day. But no odds to me, so packed the van and took off to the boat, to make a start on epoxying more deck ply pieces in place. Arrived about 9:30am. As it was still too windy and draughty through the out buildings, started with the after deck ply, as the back of the boat is out of the wind stream. These aft deck ply pieces were a real challenge. After final preperations and all equipment at the ready, set to epoxying, and in the end it all worked out remarkably well. There was no going back, or stopping once the epoxying process started, it is a time bound operation, with approx 20 minutes working time for the epoxy. The air temperature was about right so the epoxy did not cure too rapidly. I had picked up two green compost recycle buckets from the supermarket and they were working a treat one for old acetone for 1st brush wash, and the other with new acetone in. They are deep without being too wide. Real chuffed I am with myself for completing sticking down the two pieces of aft deck ply, and things will be much easier now with the side deck pieces, I tell myself. Also whilst I was sticking these pieces down, put epoxy into the two holes aft corners of the covering board to start to seal these up. I had drilled these holes out earlier today. These holes saved the day whilst the boat was outside, as they provided drainage holes for water collecting on the aft deck. They will be hidden completely by time flexiteek in place, and on the outside I plan to drill and plug them. By 15:00pm I had got the next adjoining deck ply piece stuck down on port side. This was also having managed a quick break for my salmon & tomato sandwiches with coffee, and with a touch of epoxy aroma in the air. At least the building is well ventilated so no problems there, it is just no matter how clean one is, and wearing gloves, traces of epoxy always get on your hands. Gloves are ok for mixing and painting epoxy on, but then I have to remove gloves & rinse hands in acetone to handle drill etc for screwing the ply down in place. Don’t want all the tools all gunged up. Completed the next deck ply piece aft starboard. Had had a very good day, left at 17:00pm.

|

|

|

|

|

|

27/05/08

Xtra days holiday, so down at the boat by 9:30am. No wind today, very mild and perfect for epoxy. Could I tackle the large forward piece of ply on my own ??. Decided there was no choice I would find a way how to. Spread a large piece of plastic over the forward coach roof, and laid the ply on top. The plastic will prevent drips of epoxy getting on the coach roof etc, whilst I coated it with epoxy. Then using initiative setup 12 yoghurt pots with 4 plunges each of resin in. This takes time just plunging this stuff out. On the word go, all I need to plunge out then was the hardener. It should save good 5-10 minutes. All tools and epoxy setup, and I went for it. The only awkward part was actually keeping the ply piece still whilst I coated it with epoxy as I had the pot in one hand and the brush in the other. I did it though and it went down perfectly. It works well also my masking tape along the covering board edges, cuts down on the clean up process, then after cleaning up on this ply piece and all screws and nails in place, set to sticking down the next portside side deck piece aft. All small pieces now which are easy enough to handle alone. It is using up the epoxy well, going to need to source more once this deck done. Noon now so knocked off for bacon sandwiches tainted with the smell of rubber gloves and epoxy on my hands, even though they were washed in acetone. By 15:00pm had completed all the portside deck ply, the last piece needing to be planed just a touch to fit in. By now my back was starting to ache with all this work being somewhat bent over for long periods. Packed and went home.

|

|

|

31/05/08

10:00am start, and by 12 noon I had epoxied in place the last four pieces of deck plywood starboard. Wow a fantastic job done. Once this area cleaned up, gave the rest of the deck ply a sand with the orbital.

|

|

|

Had lunch then dug out the deck/cabin side quadrants. Scribed one end into the cockpit corner external joint. Need to fix it down temporary ? How ?. Feeling tired now, had very late night last night updating Emeralds’s website and finding a further few photos of Sailing Yacht Misia the wooden Szmargd Yacht. Just packing up and sudden inspiration to mix a plunge of epoxy and fill the narrow void at the foot of the forward cabin front, where the last plywood went down. The plywood met the cabin front at right angles, so there was a angled gap. 1 plunge did the job nicely. 16:00pm finally called it a day.

01/06/08

Overcast, odd showers all day. Arrived at 9:00am & by 9:30am ready for work. Mixed 1 plunge of epoxy, and with the Iroko plugs I dug out last night, cleaned the screwholes for and epoxied in place 2 on the portside and two on starboard, where the screws fixed the cockpit side to the cockpit corner joints. Then with the remaining epoxy went round filling up some gaps which were waiting for surplus epoxy i.e. the two covering board holes aft, & just forward of the brass hatch where the last bit of ply was fixed, as it just needed the joint topping up with epoxy. Then set to cut the joint ends of deck/cabin side quadrant. The mitre saw did this nicely. Then drilled out holes 12” apart for temporary brass pins to hold the quadrant in place. For the final finish, when epoxying in place, I will use either stainless steel or silicon bronze gripfast nails – area is too small to use screws. For now tacking in place with brass pins, and the forward edge is not cut to length yet, until I shape the forward piece port to starboard, and need to work on the side deck quadrant and the cockpit corner joint. It is a real boost to see the quadrant tacked in place. Next got out the best of the two remaining 16’ lengths of mahogany 45mm x 16mm. Sanded them down with the orbital, and then hand sand and having worked out the best facing side, routered a champhered edge along both topside long edges. Then gave it a further sand before cutting in half i.e. 2 of 8’2” lengths. Taking these home, and with the bandsaw cut on in half, for the aft side deck quadrants. It is 3’o’clock now and a good day had.

|

|

|

07/06/08

During the week made good progress on the aft cockpit sides/decking quadrant, cutting the routered plank down the middle, then with the band saw again, cutting the angle on one edge. Whilst at it cut couple of 6” lengths for the cockpit corner joints/deck quadrant. Did some late shifts working this week after work, as neighbour out and carried on 7:00am this morning as neighbour away for the weekend. Just ready to go to the boat and had callout @ work thus not arrived at the boat until 11:00am. Thinking day today on the cockpit corner/deck quadrants. Both these pieces took all day, due to my learning on how to accommodate three angles in one joint. !!!. Finished by 16:00pm.

|

|

|

08/06/08

At the boat by 9:00am today. Looking at the cockpit corner/ deck quadrant I’d done yesterday, I have done it very well. Decided it was good enough and set to do the joint meeting the cockpit side/deck quadrant. By lunchtime had got these pieces temporarily fixed in place with brass pins. All is looking good. Then took a look at forward cabin to deck quadrant. Decided to use more of the quadrant size I’d been using. Anything wider would be too big. Sourced a suitable piece of mahogany and will take home to cut the angle on the bandsaw. Mitre saw has come in handy, and the flush cut saw is extremely handy for smaller delicate cuts.

|

|

Next took a look at the port cockpit corner joint on the outside, where the top of the mahogany cockpit side had weathered bad. The screw came out no problem, so cut out a section of the wood, with a view to splicing in a fresh piece of mahogany. No need for any major work here, it was not as bad as first thought. The area has cleaned up well, and should not be a big problem. Sourcing some mahogany to cut to fit in here.

|

|

Perfect weather wise and I’m sure looking forward to my up coming holiday i.e. sailing, camping and attending a woodworking course at the Boat Building Academy. Whilst out and about the plan was to pick up some needed tools, epoxy and vices for my work benches, plus stop off at some chandlerys to pick up paints & varnishes etc, all making my journeys well worth their doing. At half past 3, called it a day.

22/06/08

Spent the day down at the boat – but after having had such a good holiday, it felt like I’d been away for weeks, so took a while to switch my brain back into gear on what to do etc.

27/06/08 & 27/06/08

Spent time planning out and fitting two quick release woodworking vices to the work benches I had made. It took time and perserverance and lots of xchecking, but I managed it. These vices are a fantastic booster to allow work on the boat to continue effectively. Worked 11:00am-18:00pm and 10:30am-15:30pm.

|

|

|

|

|

|

- - - - - - This is the end of Diary Section 35 - - - - - -

![]()